Copy

SKU: 515200

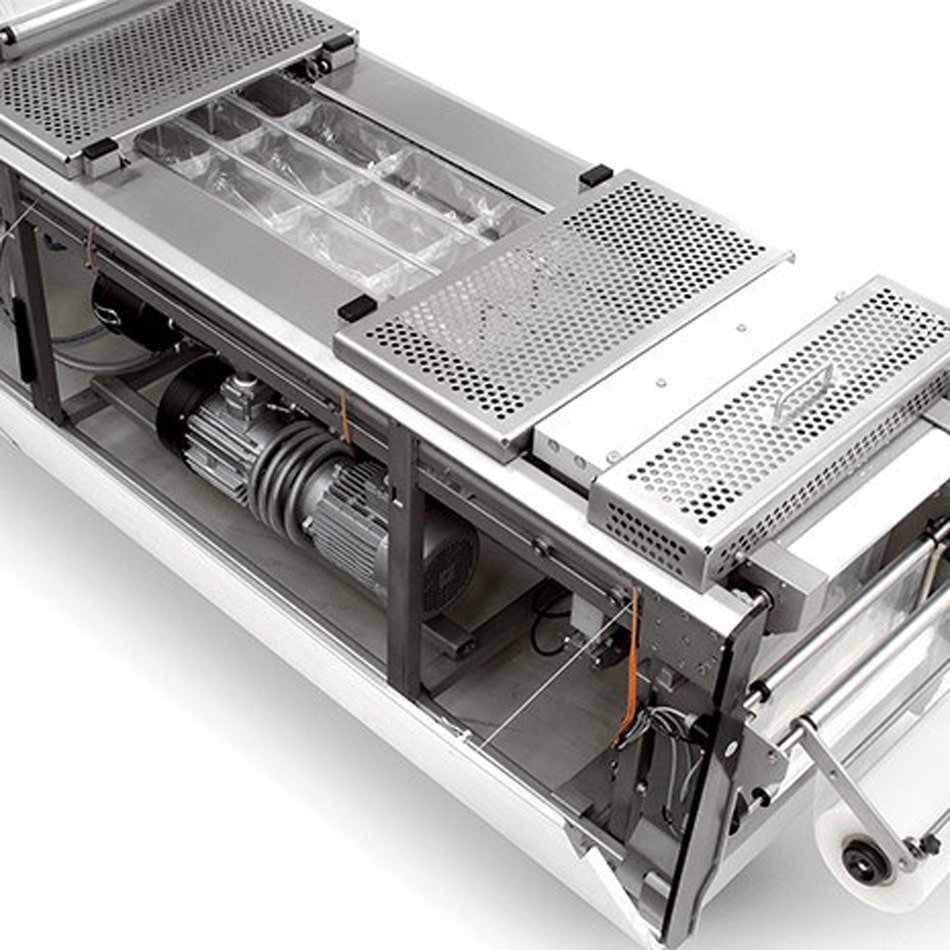

Ulma Thermoformer TFS 200

![]()

The TFS 200 is a thermoforming machine designed to pack food non-food or medical products. The package is created directly by the machine using two rolls of film. The film may be flexible or rigid. Vacuum with gas flushing is availableas an option.

The TFS series offers the ideal way to advance from manual packaging to automatic packaging. These machines provide an economical solution with the same cost saving advantages of larger thermoforming machines:

- Reduced package cost

- Increased productivity

- Improved product appearance

- Faster product loading

The machine characteristics make it highly desirable for mixed production requirements,Since formats can be easily changed to meet the needs of the customer. It’s versatile, easy to operate, and quick size change also makes it suitable as a support machine for short run products.

Features:

- Stainless steel

- 7″ Touch screen UPC control system

- Modular machine with basic structure 3000mm. (Option of 1m frame enlargement)

- Operational diagnostics

- Parameters and error messages are displayed

- CE approval

- Hygienic design, IP-65

Ease of use and maintenance:

- Highly efficient

- Tool-less detachable in-feed

- Programmable configurations

- Programmable advance speed

- Minimum maintenance

- Remote Support Management (RSM). Connection is made by Ethernet with internet access.

Optional:

Upper and lower printed film centering

Vacuum and gas flush systems

Integratable vacuum pumps 25, 63, or 100m³/h.

Special adaptations for clean rooms

Special components for very corrosive products

Integration with peripheral equipment. (Date coders, dosing system, etc)

Re-closeable zipper attachment, easy open options, zig-zag knife for easy open package

Submit An Enquiry

Please fill out this form and we will be in touch

Standard Specifications

Copy link to this section| Cycles/Min | 6 - 9 |

| Construction | Stainless Steel |

| Control System | 7" touch screen UPC control system |

| Machine Structure | Modular machine with basic structure 3000 mm. (option of 1 m frame enlargement) |

| Error Diagnostics | Operational diagnostics. Parameters and error messages are displayed. |

| IP Rating | Hygienic design, IP-65. |

| Power Consumption | 0.75 - 1.0kW |

| Electrical Specifications | 415V 32A 5Pin D Curve Breaker |

| Film Width | 420mm |

| Advance | 300mm |

| Depth of Pack (max.) | 110mm |

| Water Consumption | 60 - 100l/h, 10°C |

| Pneumatic Consumption | 300 - 500l/min, 6 bars |

| Vacuum Pump | German Busch 160m3 /h |

| Discharge Conveyor | 500mm |

Features

Copy link to this section

Construction

Stainless Steel

User Controls

7″ Touch screen UPC control system

Diagnostics

Operational diagnostics

Programmable

Configurations and advance speed

Popular Applications

Smallgoods

With black bottom webbing

Pet Food Portions

Popular for fresh mince

Bone-In Meat

With clear film

Seafood

Custom Print Available