Difference Between CPET & MAP Trays

The different terminology for different types of trays and tray sealing processes for the food industry can be confusing.

Here’s a brief explanation of the differences between CPET & MAP trays.

CPET Trays

CPET refers to the predominant plastic used in this type of tray.

CPET is a plastic commonly used for trays in the food industry, as it can be heated, and is therefore perfect for packing ready meals or similar.

However, plastic trays for food packaging can also be made out or Polypropylene (PP), Polyethylene terephthalate (PET), or Bioplastics; just to name a few options.

Every type of plastic has its own unique qualities, so choosing what type of plastic tray to use depends on your specific needs.

MAP Trays

Some may often refer to ‘MAP Trays’, MAP is actually not a type of tray.

MAP stands for Modified Atmosphere Packaging, which is a type of tray sealing process.

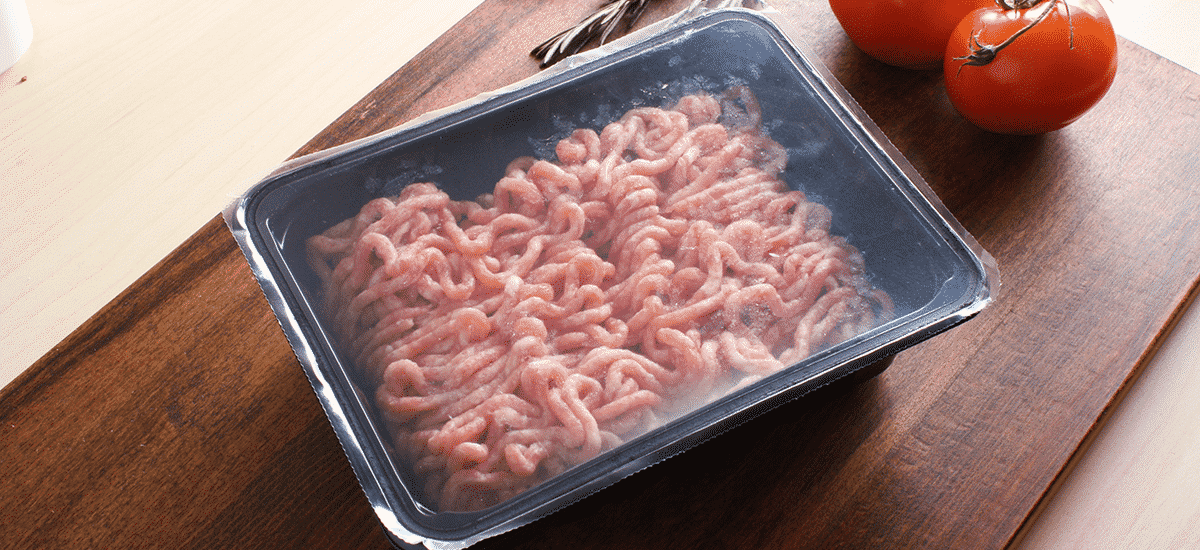

This process means that once the product is placed in a tray, the oxygen is then sucked out of the package, and a combination of food gas is pumped in to replace it.

The lidding film is then sealed over the tray, creating a modified atmosphere inside the package.

This gas mixture is specifically designed to increase a product’s shelf life, prevent the growth of bacteria, and retain freshness.

MAP is often used with fresh foods such as red meat, seafood or ready meals – and trays from various types of plastic can be used in this process.

Equipping the food industry to grow with food processing and packaging solutions

call 1300 88 99 51

email [email protected]

room 35 Shirley Way, Epping VIC 3076

room 9 Mcilwraith St, Wetherill Park NSW 2164

room 21 Hoyle Rd, Hope Valley WA 6165

room 27 Beal Street, Meadowbrook QLD 4131

room 7 Chadderton Bvd, Epping VIC 3076

room 22 Glassford Rd, Kewdale WA 6105

room 25 Hayton Road, Wigram, Christchurch 8042, NZ

Connect with us on LinkedIn